The sealing face of a flange is critical for a leak-proof connection. While many factors go into selecting a flange, choosing between a Raised Face (RF) and a Flat Face (FF) is one of the most fundamental decisions. This choice directly impacts the joint’s ability to contain pressure, its compatibility with materials, and its overall safety.

This guide explains the key differences between these two common ANSI/ASME flange face types, their ideal applications, and how to select the right one for your piping system.

Quick Comparison: RF vs. FF Flanges

This table summarizes the core distinctions to help you understand them at a glance.

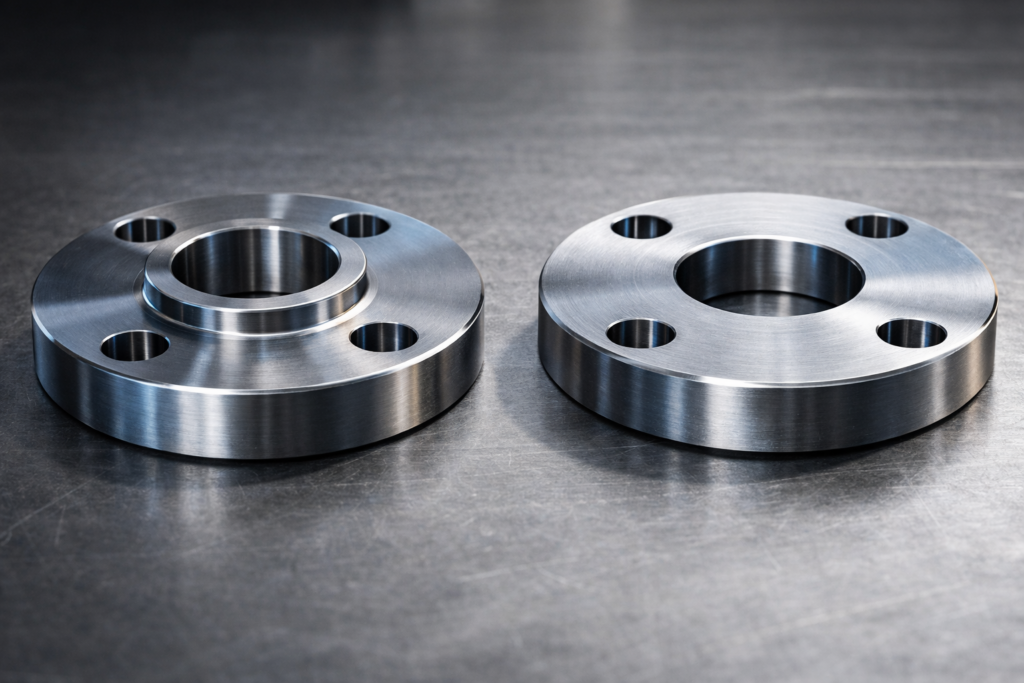

Understanding the Raised Face (RF) Flange

Design and Function

The Raised Face flange is the most common type in industrial process piping. It features a raised, serrated ring (the “face”) machined onto the flange surface, which sits inside the circle of bolt holes.

- Height: The height is standardized. For ASME B16.5 pressure classes 150 and 300, the raised face is 1/16 inch (1.6 mm). For higher classes (400, 600, 900, 1500, 2500), it is 1/4 inch (6.4 mm).

- How It Seals: When bolted, the clamping force is focused entirely on this small raised area. This creates a very high unit load on the gasket, which compresses it effectively to form a robust seal against high internal pressures.

Typical Applications and Industries

RF flanges are engineered for demanding conditions. You will find them in systems where leak prevention is critical:

- Oil & Gas Pipelines and Refineries: For handling hydrocarbons under high pressure and temperature.

- Chemical & Petrochemical Plants: Where they seal corrosive and hazardous fluids.

- Power Generation: Especially in high-pressure steam and feedwater lines.

- General High-Pressure/High-Temperature Process Piping: Any application where joint integrity is non-negotiable.

Compatible Gaskets

The design allows for use with high-performance ring-type gaskets that sit inside the bolt circle on the raised portion. Common choices include:

- Spiral Wound Gaskets (metal and filler)

- Metal Jacketed Gaskets

- Camprofile (Grooved Metal) Gaskets

Understanding the Flat Face (FF) Flange

Design and Function

The Flat Face flange has a sealing surface that is completely level from the inner bore to the outer edge. There is no raised section.

- How It Seals: A full-face gasket—one that covers the entire surface and has holes for the bolts—is used. The bolt load is distributed evenly across this large area, resulting in lower unit pressure on the gasket.

- Primary Purpose: This even distribution is not for high pressure, but for safety. It prevents the high stress concentrations that could crack or warp brittle mating flanges made of materials like cast iron, fiberglass, or PVC.

Typical Applications and Industries

FF flanges are specified for lower-severity services and specific material compatibility needs:

- Water and Wastewater Treatment Plants: For low-pressure water, slurry, and chemical lines.

- Fire Protection (Sprinkler) Systems: Where systems use cast iron fittings and pressures are moderate.

- HVAC and Building Services: Chilled water lines, heating systems, and plumbing connections.

- Pump Suctions and General Utility Lines: Where pressures are reliably low.

Compatible Gaskets

Only full-face gaskets should be used with Flat Face flanges. These are typically made from soft, compressible materials such as:

- Rubber (EPDM, Nitrile)

- Non-Asbestos Fiber (Grafoil)

- PTFE (Teflon)

How to Choose: RF or FF for Your Project?

Selecting the correct face type is a matter of matching the flange to the service conditions and system components. Follow this decision logic:

- Identify the Mating Material. This is the first and most critical check.

- If mating materials are ductile (steel, stainless steel, etc.), evaluate the Service Conditions.

- Choose a Raised Face (RF) flange if:

- Choose a Flat Face (FF) flange if:

⚠️ Critical Rule: Never bolt a Raised Face flange directly to a Flat Face flange. The RF’s raised surface will concentrate all the force on the small contact area of the FF flange, which can cause it to bend, crack, or fail to seal. If such a connection is unavoidable (e.g., connecting a steel RF flange to a cast iron FF flange), the raised face must be machined flat, or a special full-face adapter/gasket must be used.

Frequently Asked Questions (FAQs)

1. Can I use a ring gasket on a Flat Face flange?

No. Using a small ring gasket on an FF flange is incorrect and dangerous. The bolt load would be concentrated on the small gasket area, potentially warping the flange and causing a poor seal. FF flanges must use a full-face gasket.

2. What is the standard surface finish for these flanges?

Both RF and FF flanges under ASME B16.5 typically have a serrated finish with a roughness between 125 to 250 micro-inches (3.2 to 6.3 µm Ra). This “serration” helps grip the gasket and improve the seal.

3. Are there other common flange face types?

Yes. Besides RF and FF, two other important types are:

- Ring-Type Joint (RTJ): Used for very high-pressure services (e.g., wellhead equipment). It uses a metal ring gasket seated in a precision groove.

- Tongue-and-Groove (T&G) / Male-and-Female (M&F): Used where precise alignment and leak-tightness are critical, often for seal pans or heat exchangers.

4. Does pressure class affect the Raised Face height?

Yes. As noted in the ASME B16.5 standard, the raised face height increases for higher pressure classes to accommodate the greater bolt load and provide more robust gasket compression.

5. Is a Raised Face flange always more expensive than a Flat Face?

Generally, yes, due to the extra machining step for the raised surface and the common use of more expensive, high-performance gaskets. However, the cost difference is often negligible compared to the total installed cost and risk of failure. Always choose based on technical requirements, not just initial cost.

Conclusion

Choosing between a Raised Face and a Flat Face flange is a foundational engineering decision. Remember:

- Use Raised Face (RF) for strength and superior sealing in high-pressure, high-temperature, or critical service applications with ductile materials.

- Use Flat Face (FF) for safety and compatibility with brittle materials like cast iron or for simple, low-pressure utility systems.

The wrong choice can lead to leaks, joint failure, or damaged equipment. When in doubt, consult the relevant ASME B16.5 standard or work with a qualified piping engineer or reputable flange supplier. For a broader understanding of flange specifications, you can refer to our guide on ANSI flange dimensions and standards. By applying the principles in this guide, you can ensure your flanged connections are safe, reliable, and fit for purpose.